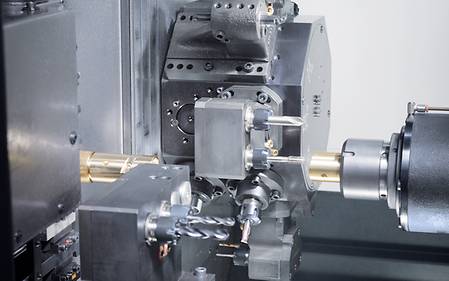

SPRINT 42|10 linear

The flexible design for long and short turning parts

Max. workpiece diameter

2 in.

42 mm

Max. workpiece length

13 in.

320 mm

Max. bar capacity diameter

2 in.

42 mm

Max. X-axis stroke

2 in.

50 mm

Max. Y-axis stroke

14 in.

350 mm

Max. Z-axis stroke

5 in.

120 mm

Control & software alternatives

Fanuc

Highlights

Automatic turning with 8 linear axes and 2 C-axes

- Main spindle with 6,500 rpm, 37,5 Nm, 5.5 kW (nominal)

- Counter spindle with 6,500 rpm, 19.6 Nm, 3.7 kW (nominal)

- SWISSTYPEkit optional for short and long part turning on one machine

Total of 30 tool stations

- Turret with 16 stations; up to max 22 driven tools total

- Driven tools spindles 5000 rpm, 2.2 Nm, 0.55 kW (nominal)

- Linear drive in X1 and X3 with 1 g acceleration for fastest dynamic and accuracy

DMG MORI SLIMline featuring a 15" screen with FANUC 310i

- 3 control channels, 8 linear axes and 2 C-axes

- Tool Monitoring System with graphical tool load display as option

- Up to 3 tools working simultaneously

Highest rigidity and accuracy

- Constant stiffness due to large ball guide ways with balanced distance

- Vertical covers and free chip fall

- Integrated spindle motors for main and counter spindle with direct measuring systems

- Thermo-symmetric machine bed design for highest accuracy

Application Examples

Control & Software

Experience the speed of digital transformation (DX)

Revolutionize your operations, unlock new opportunities, increase efficiency and promote sustainability by reducing power consumption – while gaining a strong competitive advantage.

Service & Training

Comprehensive carefree service and training for your production

Take advantage of our full-service offering and hands-on training to maximize machine performance and minimize downtime. With comprehensive maintenance packages, original spare parts and tailored training programs, we can take your production and your team to the next level.

Downloads & Technical Data

Work Area

Max. X-axis stroke

2 in.

50 mm

Max. Y-axis stroke

14 in.

350 mm

Max. Z-axis stroke

5 in.

120 mm

Workpiece

Max. workpiece diameter

2 in.

42 mm

Max. workpiece length

13 in.

320 mm

Max. bar capacity diameter

2 in.

42 mm